Fingrid’s Construction Manager Keijo Välimaa has been running construction operations since 2000.

”In the early 2000s, we mostly relied on the contractor to take responsibility for its operations. We monitored the situation but generally only reacted to events after the fact.”

The volume of construction has increased during the 2000s and contractors now use more subcontractors. A lot of new operators have entered the industry, also from other countries. Detailed procedures are agreed upon in the contract agreements.

“Today’s agreements are much longer, in part due to the increase in safety requirements.”

Active development of safety

In recent years, the focus of occupational safety has shifted to proactive work. For example, the subject is continuously highlighted during the regular toolbox talks held at worksites. Digital technology, such as a web-based reporting system, also promotes development.

All people working at Fingrid worksites must complete the company’s online school, which is available in many languages. Fingrid also offers electrical work safety training for other industry operators. Tests that must be completed in an approved manner are held to ensure that the required qualifications are achieved.

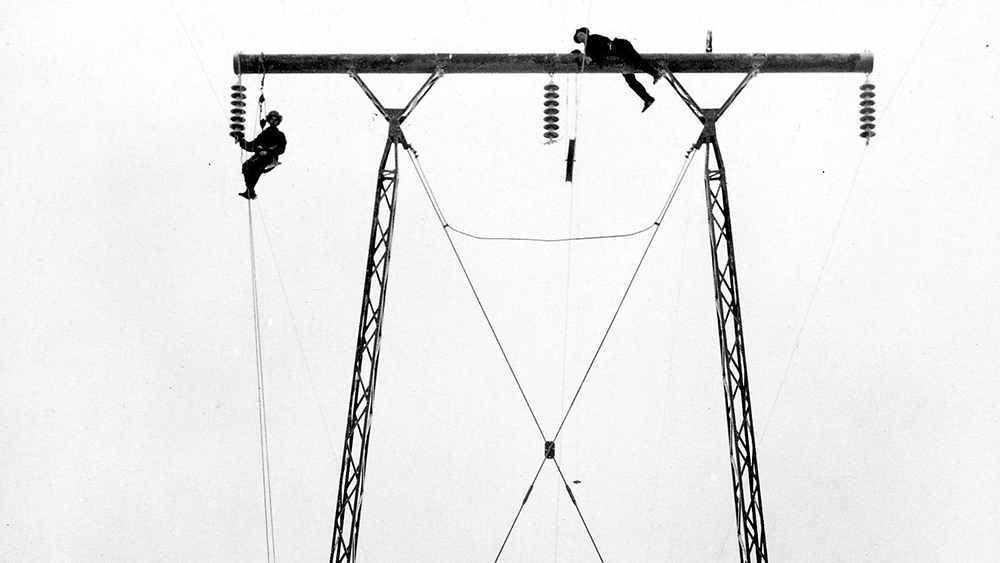

We took a big step forward in 2005 with the decision to equip all new towers with a safety ladder structure. This large investment was considered an important move. We’re currently examining car travel from the occupational safety perspective. Experts drive tens of thousands of kilometers between worksites, often in poor conditions.

“It would be logical to spend most of the working hours on expert work rather than driving from place to place.”

Things weren’t always better in the good old days

For Worksite Manager Tauno Nieminen from Infratek, switching from a building construction worksite to electrical networks meant a change in his occupational safety thinking.

Nieminen’s first worksite on the electricity distribution side was the electrification of Rauhalahti peat power plant in 1984.

“Helmet use wasn’t compulsory in construction work at that time and aps were a common sight at worksites. We had to wear a helmet at the power plant worksite, and it even saved my life once. Since then, the importance of safety gear has been obvious to me.”

Nieminen also remembers the negative attitude towards safety shoes.

“I bought a pair of safety shoes with my own money when I was 15, and the more experienced men laughed at me. I didn’t wear the shoes, and of course that resulted in an accident.”

Today, Nieminen’s job as a worksite manager includes providing induction for new employees. He says that he has received good feedback about his activities at worksites.

“The most important part of safety training is setting an example. It’s hard to ask others to do more than you’re prepared to do.”