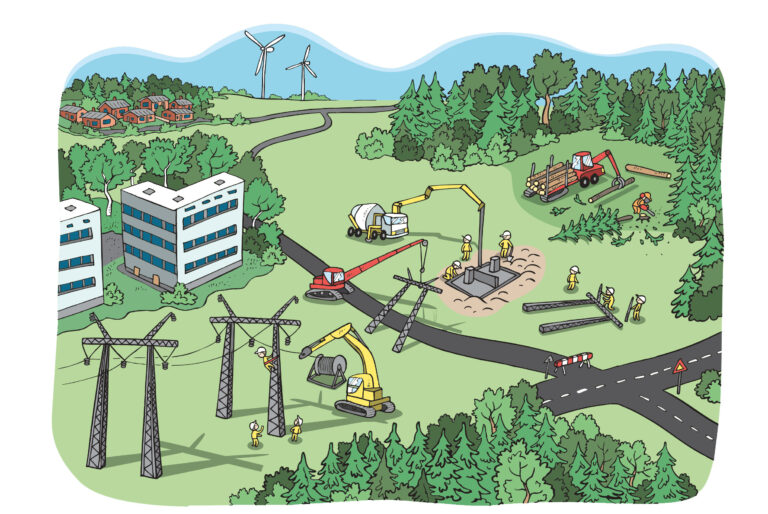

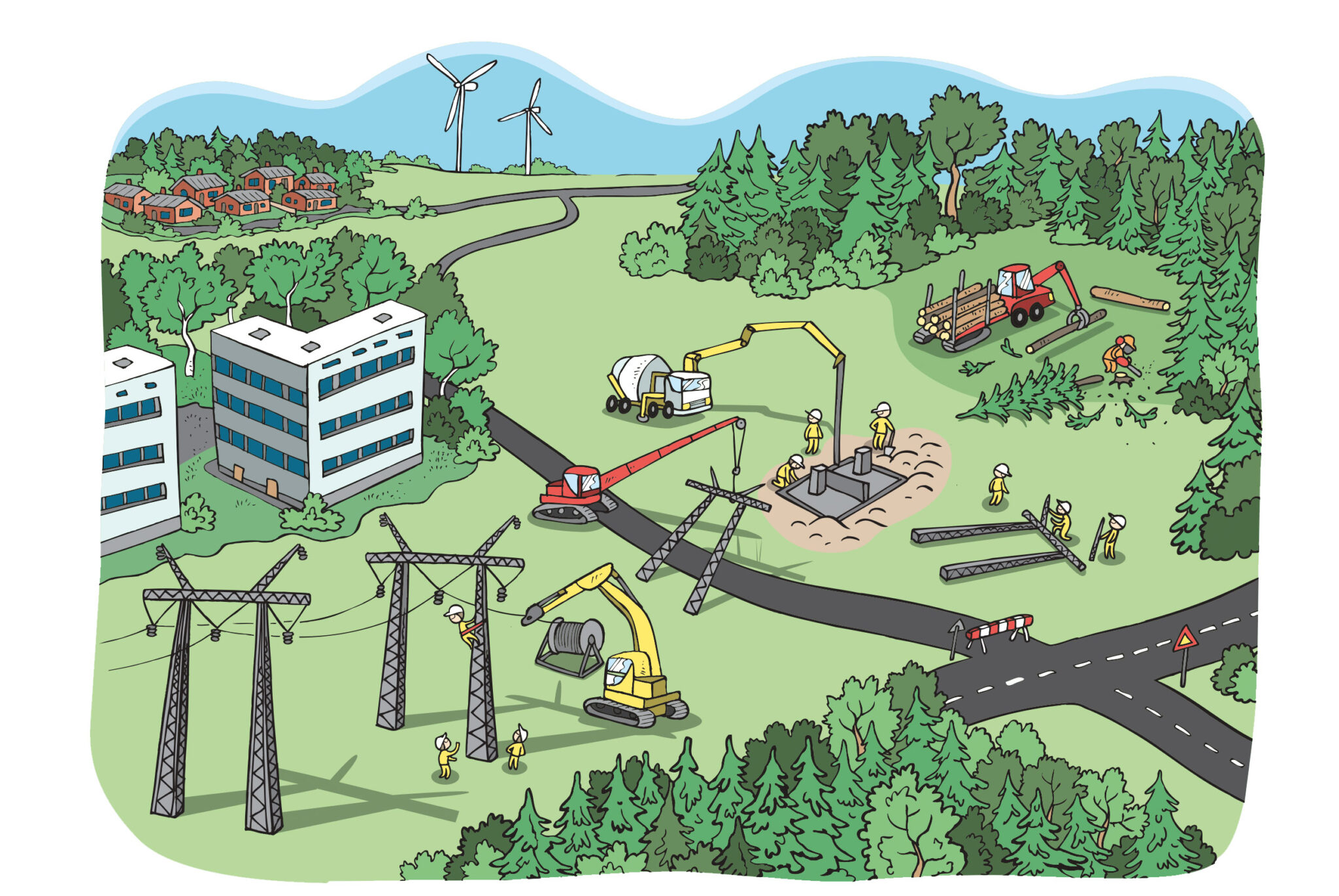

Electricity networks are in a state of whirlwind development. This programme of significant investments in the main grid is necessitated mainly by Finland’s shift towards carbon-neutrality and its focus on renewable energy generation.

“At this stage in our grid investment programme, we are mostly connecting our customers’ generation and consumption facilities to substations. Construction is focusing first on substations, but it will then shift to transmission line construction,” says Daniel Kuosa, Construction Manager at Fingrid.

Last year, there were approximately 50 substation projects. This year, the number will approach 70.

Fingrid has budgeted EUR 200 million for substation investments this year. The project portfolio extends several years into the future and involves EUR 430 million of investment. Last year, there were approximately 50 substation projects. This year, the number will approach 70.

The work to expand the Jylkkä substation, which will be completed this spring, exemplifies the new needs. The 1,250 megawatts of wind power capacity in the Kalajoki and Pyhäjoki region requires three large transformers to bring this renewable electricity to the national grid. To put this scale into context, the new Olkiluoto 3 nuclear power plant will output 1,600 megawatts.

In addition, investment needs are increasingly arising due to electricity consumption. Investments are being made in areas such as battery factories, data centres, power to X plants that produce renewable fuels, heat pumps, and electric boilers.

Switchgear and transformer substations

“Substations are like the electricity grid’s synapses – they are hubs that connect the network’s transmission line,” Kuosa says.

Substations can be divided into two types: switchgear and transformer substations.

Switchgear connects different parts of the network together. For example, in the event of a fault, the switchgear can switch off a certain part of the network automatically and switch it back on automatically.

Air-insulated switchgear, which is out in the open, surrounded by a wire mesh fence, is a familiar sight to many of us. Nowadays, gas-insulated indoor switchgear is increasingly built as an alternative, as it looks like an ordinary building from the outside.

The protective relays and automation systems at substations constantly measure the network’s status, regulate the voltage, search for faults, and detect if there is too much current. In the event of a fault, they trip the faulty network component off the grid in a matter of milliseconds.

Transformer substations alter the voltage of the network. The voltage is lowered in steps as electricity comes nearer to the point of consumption.

Fingrid operates at the 400 kV, 220 kV, and 110 kV voltage levels. Large transformers – the size of a house – reduce the voltage from 400 kV to 110 kV and connect to customers such as distribution networks, production plants, and industrial facilities.

The largest generators and consumers of electricity connect directly to the 400 kV network at substations.

“The power transformers in the main grid are very heavy units, weighing up to 300 tonnes. Simply transporting them to their final location places major demands on the infrastructure,” Kuosa says. In the past, power transformers have been brought to Finland all the way from South Korea.

The other high-voltage equipment in substations includes circuit breakers, disconnectors, and instrument transformers, although, to the uninitiated, they may all look like the same kinds of insulators.

Evolution not revolution

The technical service life of a substation is calculated at approximately 40 years, but large system transformers can be used for up to 80 years with effective maintenance.

Daniel Kuosa describes how safety is at the heart of development work. Digital technologies have been adopted step by step over time.

“The greatest benefit of digitalisation is in condition management, where sensors monitor and measure components to help keep them in good condition.”

Environmental impacts of substations are taken into account in increasing depth.

The environmental impacts of substations are also taken into account in increasing depth. For example, SF6 gas has been widely used in gas-insulated switchgear thanks to its favourable properties. The downside is that SF6 is a potent greenhouse gas, so efforts are now being made to find substitutes.

Fingrid built its first substation without SF6 gas in Virkkala.

“Our targets are ambitious: after 2025, all our new gas-insulated apparatus will be free of SF6 whenever it is technically possible,” Kuosa says.

In addition, studies are underway to examine the use of biodegradable ester oil instead of mineral oil as an insulator in transformers.