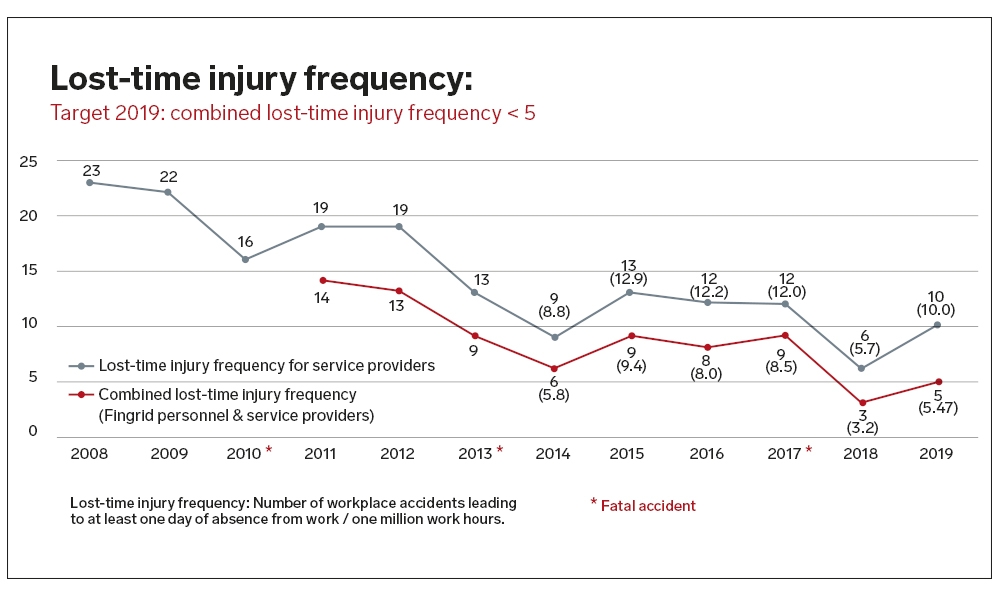

Seven workplace accidents occurred resulting in absences, two of which were classified as serious accidents. The interim target for the combined lost-time injury frequency in 2019 was less than five (workplace accidents leading to absences / million working hours). The frequency ended up being 5.5, so we did not reach this target.

Three of the workplace accidents occurred on transmission line investment sites, one in transmission line maintenance, one in a substation project, one in substation maintenance, and one in vegetation management. Slips and trips were the causes of about half of the workplace accidents leading to absences. It is noteworthy that there were three accidents caused by rotating blades in machinery. One of these was a serious accident leading to a permanent disability when the blade of a brush saw severed an employee’s finger.

Another serious workplace accident occurred on a transmission line investment site when an employee slipped on a forestry machine platform and injured his arm. This accident led to sick leave lasting more than 30 days.

The same causes were behind the accidents as in previous years: slipping, uneven terrain and inadequate safety planning in unforeseen circumstances. Accidents often occur when situations change, so it is important to suspend work if an unforeseen event arises and take enough time to plan the work safely.

Proactive occupational safety work continued on Fingrid’s worksite this year. The number of safety observations and near misses increased slightly year-on-year. The majority of the observations were made on substation and transmission line investment sites, but there were also some observations in maintenance.

The number of safety observations has increased in recent years, and employees have contributed to the joint development of occupational safety at a pleasing rate. In addition to the quantity of safety observations, the quality and the things that we learn from them are also important. Approximately 500 safety toolbox talks were held on Fingrid’s worksites, which is about the same number as in 2018.

In 2019, there were no near misses falling in severity category A. However, there were more than ten near misses in the medium-severity category, B, including the following:

- Incidents of the ground giving way during lifting work caused three moderately severe near misses. None of these incidents involved the hoist falling over, but if the ground gives way, there is always a risk of personal injury and significant material damage. The reasons for these incidents were either inadequate hoist bedding or misjudgements of the load-bearing capacity of the ground.

- One forestry machine came close to falling over after slipping on a snowy and icy slope.

- The lack of a design for a prefabricated construction element led to a hazard when it became apparent that the prefabricator

had made the support holes too small, resulting in the risk of elements falling over in high winds. Fortunately, the supplier noticed the mistake before any installation work began. - When a conducting wire was being pulled through, the conductor’s span wire snapped when the conductor was overtightened to allow for insulators to be installed. The conductor did not fall down because a brake machine was used as a backup.

- A tower was being demolished on a transmission line project when it fell onto the live 20 kV transmission line next to it. No measures had been taken to prevent the demolished tower from falling onto the adjacent line.

- On a substation project, the overhead line’s jumpers attached to the horizontal beam of a switchyard caused a three-phase short circuit during commissioning.

- A live cable also caused a hazard when a gas analyser was being installed in a transformer, as the installation technician thought that the cable was not live.

A total of nine corporate responsibility audits were performed on substation and transmission line projects, reserve power plant projects and vegetation management sites in 2019. Corporate responsibility audits are Fingrid’s way of ensuring that the activities on the worksite comply with the requirements of Fingrid and the laws in occupational safety and environmental matters, as well as employee

responsibility matters.

There was found to be room for improvement in areas such as risk assessments, identifying particularly hazardous work locations, competence management and online training completion, and lifting equipment. It is good to see that suppliers have welcomed feedback and suggestions for improvements. Development has occurred in terms of MVR measurement competences, the quality of safety plans and, at the end of the year, the condition of lifting equipment. About ten corporate responsibility audits will be conducted in 2020.