The overhead lines that Fingrid uses have a galvanised steel core with aluminium strands wound around it.

“Aluminium has good electrical conductivity and corrosion resistance,” says Rami Isomäki, Project Manager at Fingrid, regarding the importance of aluminium.

Aluminium extracted from the soil is bound with other minerals and requires a smelting phase—electrolysis—to extract it, which consumes a great deal of electricity.

Conductor suppliers in China and India have begun buying aluminium ingots from smelters whose hydrolysis processes use renewable energy, such as hydro, wind, or solar power. These zero-emission energy sources yield what we call green aluminium.

Fingrid defines aluminium production as green when 95 per cent of the electricity used for smelting is fossil-free.

“Green aluminium itself is the same as any other aluminium; the only difference is that the energy source is renewable instead of fossil fuel,” says Isomäki.

Dramatic drop in emissions

In spring 2023, Fingrid prepared a report indicating that 70–75 per cent of Fingrid’s carbon footprint comes from aluminium conductors.

“Each tonne of aluminium produced using fossil fuels results in approximately 16 tonnes of emissions. Switching to green aluminium reduces this figure to around 4 tonnes, slashing emissions to a quarter of their previous value. We can reduce our carbon footprint enormously by purchasing conductors made from green aluminium,” says Isomäki.

Could conductors be made from recycled aluminium?

“No, because conductors require high aluminium purity, which is almost impossible to achieve with recycled aluminium.”

Fingrid’s values call for it to reduce its carbon footprint. The EU’s Carbon Border Adjustment Mechanism is another good reason to use green aluminium. The mechanism is meant to put a price on the carbon emitted during the production of products imported into the EU.

“In practice, this means that if you import aluminium produced using fossil fuels into Europe, you will need to pay for it from 2026. The Carbon Border Adjustment Mechanism will take full effect in 2034.”

Fully green deliveries

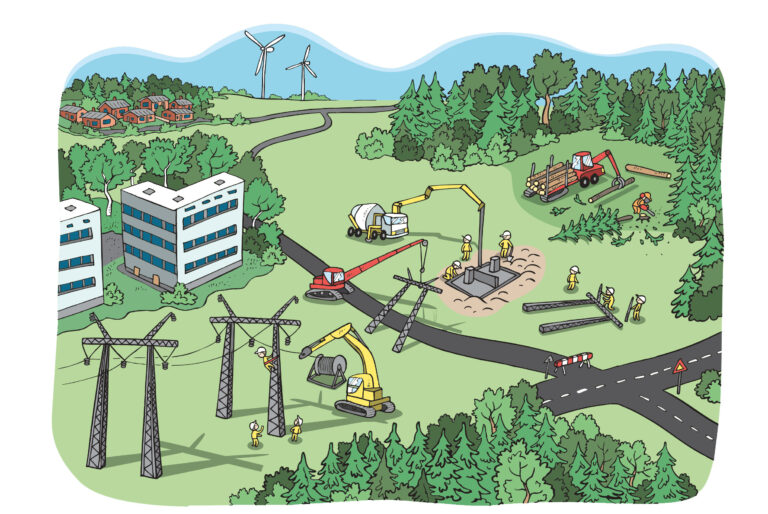

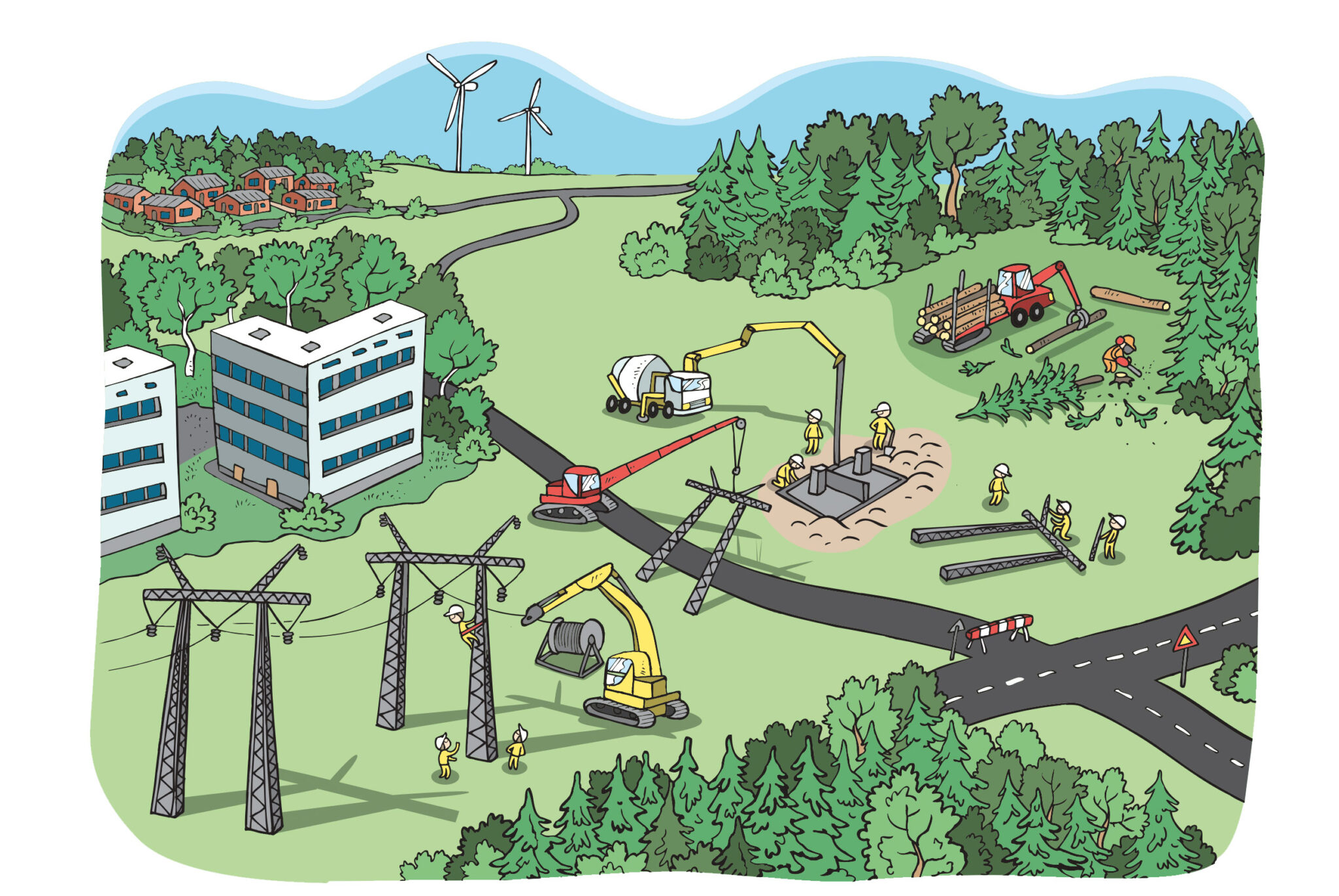

At the beginning of the year, Fingrid received its first lots of green aluminium conductors from two suppliers and used them on the Aurora Line, Siikajoki–Sorsaraivio, and Huittinen–Forssa worksites. Fingrid found the trial lots flawless and has since received many more lots.

“We made new conductor agreements in the summer, requiring only green aluminium to be used in the conductors. We have also amended our existing agreements with ZTT Group of China and Sterlite of India to require green aluminium,” Isomäki says.

Since May, only green aluminium has arrived on Fingrid’s sites.

Fingrid as a pioneer

Joseph Jin, Nordic Sales Manager at ZZT Group, a manufacturer of conductors, says Fingrid’s forward-looking operations provided the impetus for ZTT Group to build a green supply chain.

“We met with Fingrid in April 2023, and they enquired about the possibility of using emission-free electricity to manufacture aluminium.”

“Fingrid is the first European transmission system operation to which we supply green aluminium wires.”

In the same year, ZTT Group sought out qualified aluminium suppliers.

“Third-party organisations have certified the Chinese green aluminium products to ensure quality and compliance,” says Jin.

Currently, 1.81 per cent of the aluminium in ZTT Group’s wires is green aluminium, but the company plans to gradually increase production to 100 per cent.

“Fingrid is the first European transmission system operator to which we supply green aluminium wires. The transmission system operators in other European countries, such as Germany and Sweden, are still biding their time, but we see growing market interest in green aluminium.”