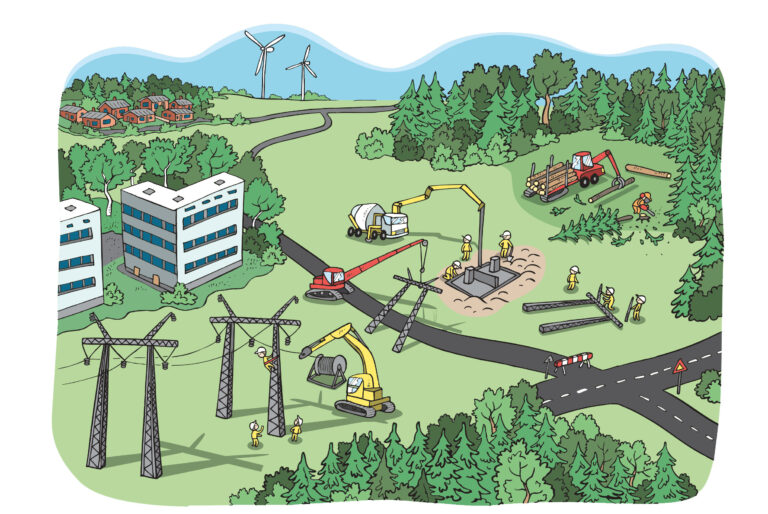

Fingrid is committed to reducing the negative climate impacts of power grid construction.

Together with its partners, the TSO is developing solutions for reducing the environmental impact of its operations. The company actively monitors the availability and suitability of low-carbon structures for grid construction.

The TSO is looking for more sustainable alternatives for the steel used in substation structures, which has a significant carbon footprint.

Low-emission steel used in Harjavalta, Nakkila and Kokemäki

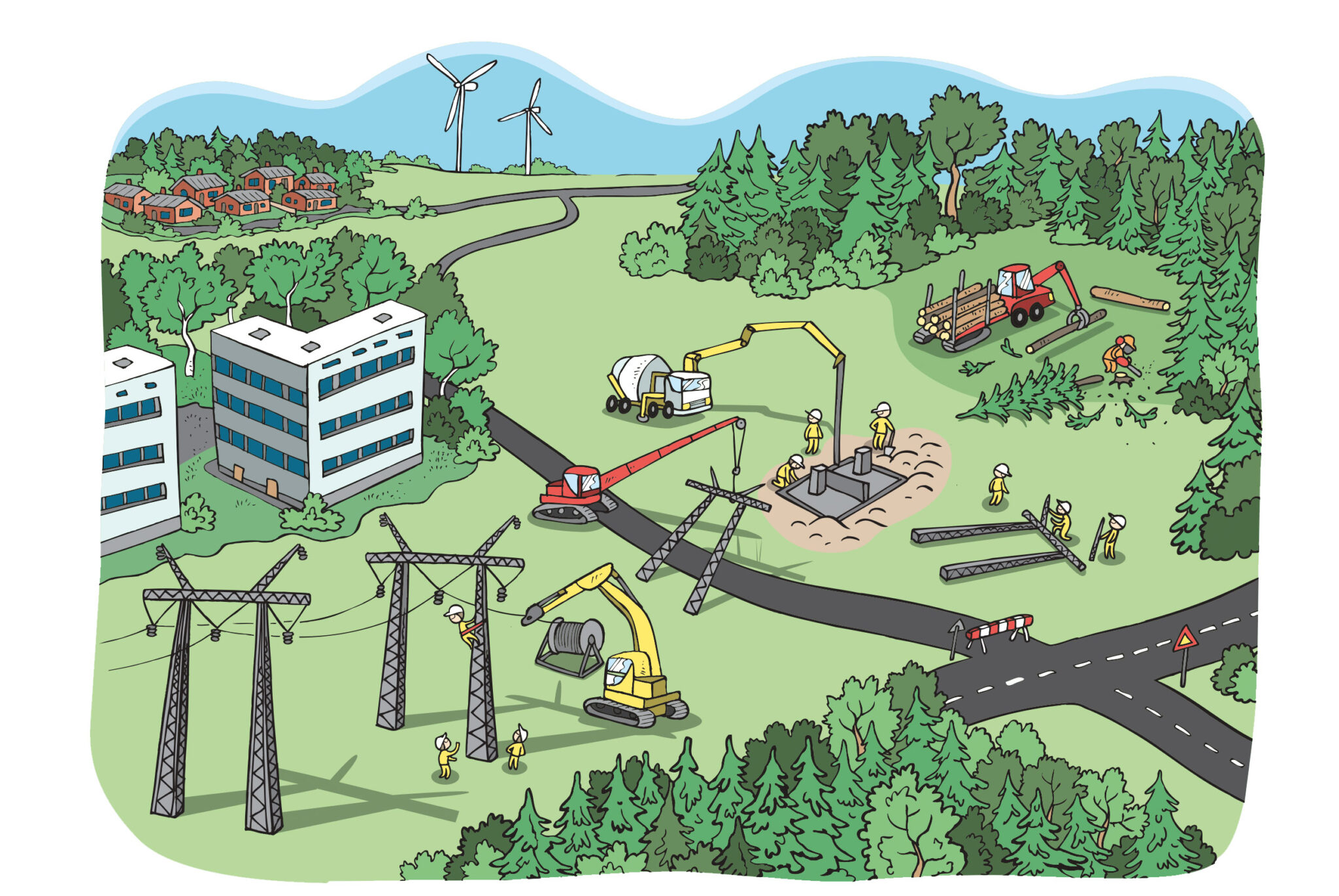

Fingrid is building three new 110-kilovolt substations in Harjavalta, Nakkila and Kokemäki together with Enersense. For the first time, the steel structures for these substations will be made of recycled steel.

Main grid construction is now at an all-time high, which improves Finland’s competitiveness in attracting industrial investments and contributes to the achievement of Finland’s carbon neutrality goals by 2035.

Enersense supplies all of the steel structures to be built in the yards of the substations, which require 76,000 kilogrammes of steel in total. The structures consist of termination portals for 110-kilovolt power lines, of which 14 will be needed for connecting the power lines.

The portals are made of hot-dip galvanised steel. Enersense, through its partners, will procure all steel structures in low-emission steel, which reduces carbon dioxide emissions by an estimated 40% compared to structures manufactured with the traditional method from iron ore.

The project uses recycled steel, avoiding the need to reduce iron ore.

The project uses recycled steel, avoiding the need to reduce iron ore.

“The production of steel from iron ore with the traditional blast furnace process generates large carbon dioxide emissions. In this project, we circumvent the need to reduce iron ore by using recycled steel,” says Sampsa Launiainen, Fingrid’s structural expert in the projects.

Substations play a key role in electricity transmission, security of supply, and grid status management. New substations guarantee a reliable power supply for local industry and projects.

Increasing demand for emission-free products

There is growing global demand for products whose manufacture does not generate carbon dioxide emissions.

Fingrid’s Project Manager Ville Viita and specialist Sampsa Launiainen are happy with the project regardless of challenges in the availability of low-emission structures.

Interest in low-emission steel is growing.

“Interest in low-emission steel is growing, and this is a valuable pilot project. Enersense has worked really hard to find suitable suppliers across Europe,” says Viita.

Launiainen continues:

“Availability is currently very poor, but there can be no supply without demand. This is a valuable pilot – it shows steel manufacturers and wholesalers that it’s a good idea to make low-emission steel. We are happy to note that global interest has increased.”

Pioneer in low-emission steel

Steel production is one of the world’s largest sources of carbon dioxide emissions, as the current production methods rely heavily on coal.

In the winter, Fingrid participated in WWF’s Green Steel project, which aims to accelerate the transition to low-emission steel production and increase the availability of low-emission steel.

The demand for low-emission steel is growing, which this pilot project by Fingrid and Enersense aims to show to steel manufacturers and vendors. The project emphasises commitment to greener choices and encourages the steel industry to develop more sustainable production methods.

“Environmental issues are very important to me and to Fingrid. It’s great to be involved in a project that makes concrete steps towards the green transition,” says Viita.

New SF6-free technology

The vision of Fingrid’s sustainability work is a main grid that does not generate any SF6 emissions.

Sulphur hexafluoride (SF6), which provides excellent insulation, has traditionally been used in the circuit breakers of electricity transmission switchgears. However, SF6 is a very harmful greenhouse gas when emitted into the atmosphere. Fingrid is committed to reducing the use of SF6 gas in its substations and to promoting the adoption of new technologies.

These substation projects will be implemented as gas-insulated substations (GIS) using an insulating gas that does not contain climate-warming SF6 gas.

Substituting SF6 with low-emission insulation gas can significantly reduce greenhouse gas emissions over the substations’ life cycle.