Two digitalised bays are being built alongside the traditional system at Pernoonkoski substation near Kotka. Information moves digitally between the high-voltage equipment located outdoors and the protection and control devices inside the control room.

The aim of digitalisation is to lower construction and maintenance costs. From the perspective of the customer and society, it also provides more reliable power transmission.

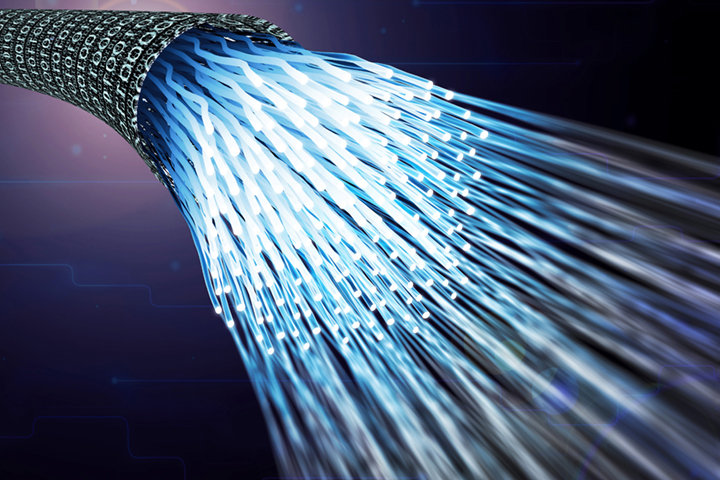

From copper cables to optical fibre

While a traditional substation contains kilometres of copper cable and every filament of that cable transmits its own bit of data, a digital substation uses optical fibre for the same purpose.

Fingrid’s Construction Manager Daniel Kuosa explains that the goal is a system that could be added to completely new substations or to old substations that are being renovated.

Once the experiences from the Pernoon- koski pilot have been analysed, Fingrid will begin test operation of the first fully digital substation. Those results will provide information about a possible schedule for more widespread digitalisation,

Benefits include testability and monitoring

Digital systems can be built and tested before they are delivered to the substation. The system can also be set up for self-monitoring. For example, proactive maintenance and periodic testing may no longer be necessary. The system can also be programmed to simulate different situations that occur at a substation.

Replacing copper cable with optical fibre saves space. The only power cables left at the substations would be those needed to provide the actuators with electricity. Traditional substation buildings could be replaced with, for example, smaller modular containers.

Digital substations are also safer and more environmentally friendly than traditional substations.

The system has to be accurate and fast

Since electric phenomena happen fast in the grid, the system must be able to react to them quickly.

“All the devices have to know exactly what time it is. Otherwise they don’t work properly,” explains Kuosa.

He explains that it’s important for the devices to be compatible and not bound to a single manufacturer. This requirement ensures that they can be changed.

Above all, the Pernoonkoski pilot represents an opportunity to learn.

“There’s never a single correct way to operate. Experimenting allows us to find the right solutions,” says Kuosa.