According to Fingrid’s occupational safety expert Karri Koskinen, the company’s long-term occupational safety project has begun to produce results. Occupational safety models and tools have been improved. The company’s personnel and partners have been coached to act responsibly at worksites.

“Our goal of zero accidents depends on people. We get results when every employee is committed to the occupational safety targets and takes responsibility for themselves and their co-workers,” says Koskinen

Fingrid and its service providers have a clear division of work regarding occupational safety responsibilities.

“We have the contractor’s obligation and liability for investments and maintenance. Our occupational safety coordinator ensures that the main executor of the work in question handles its safety obligations in accordance with the legislation and Fingrid’s requirements,” says Koskinen.

A service provider performing practical work is responsible for ensuring that the agreed plan is observed at worksites and risk assessments are performed for the implementation phases of the work.

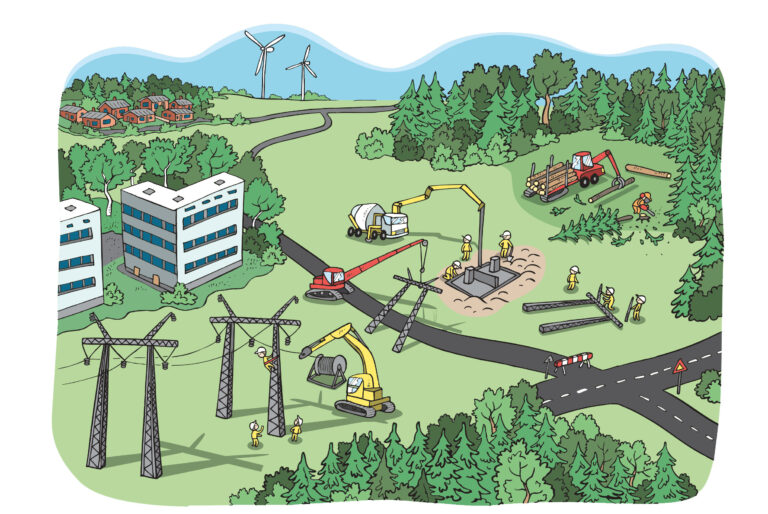

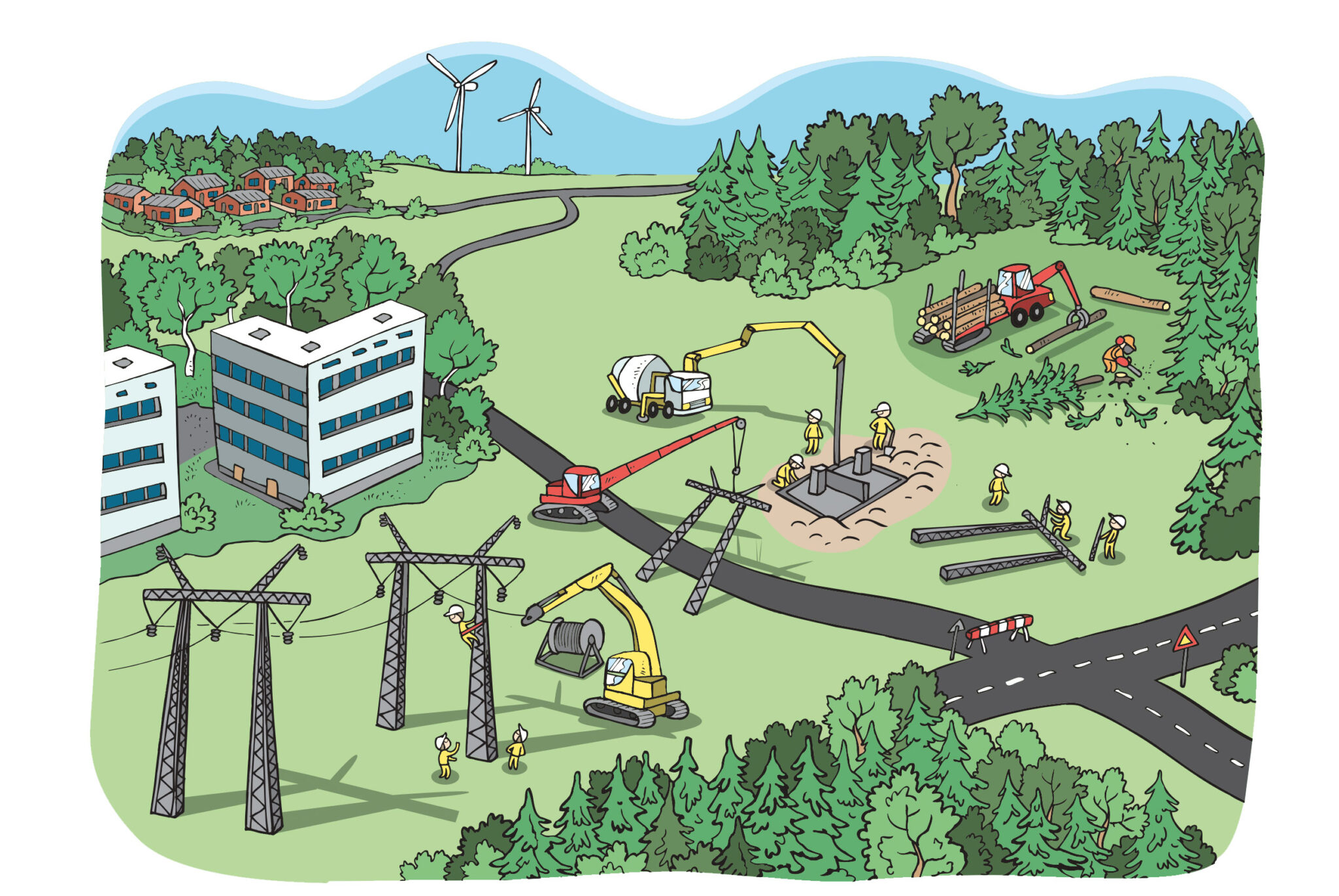

Fingrid’s worksites have special requirements

In addition to the general terms of occupational safety legislation, people working at Fingrid worksites are required to comply with contract terms concerning safety.

“For example, the qualification requirements for our worksites include Fingrid’s online school, an occupational safety card as well as first aid training and skills tests for employees working in towers,” explains Koskinen.

There are a lot of risk factors associated with working near electrical equipment, which means that specialisation in electrical safety is also required from service providers. People move around a lot at transmission line worksites, and this increases the risk of accidents. This means that it’s important to pay special attention to the work environment, terrain and movement and ensure that the required safety equipment is used.

Focus on equipment and tidiness

People working on construction worksites must wear safety shoes, reflective clothing, eye protection and a helmet with a chin strap. Employees must also carry an identification card with a photograph and tax number.

“A written warning for deficiencies in safety equipment is always issued to the employee, and the subcontractor receives a claim and a penalty,” says Koskinen.

The most significant safety concerns at Fingrid worksites are risks associated with induced voltage, moving around and working at height.

“Our online school modules and the Safety on the Lines publication for service providers contain good practices concerning how to prevent dangerous situations.

Tidiness and cleanliness at worksites also affect occupational safety, because slipping and stumbling are often caused by deficiencies in these areas.

Worksite tidiness is also part of the circular economy. Lassila & Tikanoja is responsible for recycling construction waste at Fingrid worksites.

A vision of risk- and condition-based maintenance

Equipment also has a major impact on occupational safety. The focus of power line and substation maintenance is now moving more towards proactive, risk- and condition-based maintenance.

The goal of Fingrid’s KUHA2021 development programme is to bring together all the areas of maintenance and use new operating methods to provide an even stronger grid for customers and society.

“Risk- and condition-based maintenance aims at more efficient utilisation of existing resources. The resources are targeted at places where risk can be reduced most in relation to the investment,” says Kimmo Nepola, a specialist in Fingriid’s HVDC unit.

Nepola emphasises that while every customer and site is equally important, some sites are more critical because of their risk impact.

“Along with safety, the risks can be economical or related to system security or the environment,” explains Nepola.

The rapidly changing maintenance sector requires that service providers and contractors have the readiness to change according to the requirements. Nepola says that measurement data is increasingly important in risk- and condition-based maintenance. Rather than focusing on regular annual inspections, the goal is to organise maintenance in a proactive manner based on where measurements indicate a real need.

The Internet of Things (IoT) is bringing new dimensions to the collection of measurement data. Fingrid is currently testing sound sensors in main grid monitoring. These sensors send data from grid devices to Fingrid’s data systems on a non-stop basis.

“We receive proactive and cost-effective information about the condition of the devices when the power is on. This allows us to improve main grid functioning and reduce the number of disturbances,” says Nepola.