Jarmo Partanen, Professor of Energy Engineering at LUT University, considers the project a highly significant step towards a climate-neutral future and believes that it also has strong export potential. LUT University has been testing the technical functionality of the process since 2017, and it has modelled the alternatives for transforming the pilot project into a profitable production plant.

“Finland has a good head-start in terms of synthesising methanol, as we have a lot of different individual sources of carbon dioxide, and the increase in wind energy enables electricity to be generated inexpensively. Recycling carbon dioxide from industrial emissions offers Finnish companies a major opportunity to make fuel production carbon-neutral,” says Partanen.

Synthetic methanol is created when carbon dioxide and hydrogen are combined in a chemical process. Methanol can be used to manufacture fuels for transportation, such as petrol, kerosene or diesel. These can replace fossil fuels, which cause climate change.

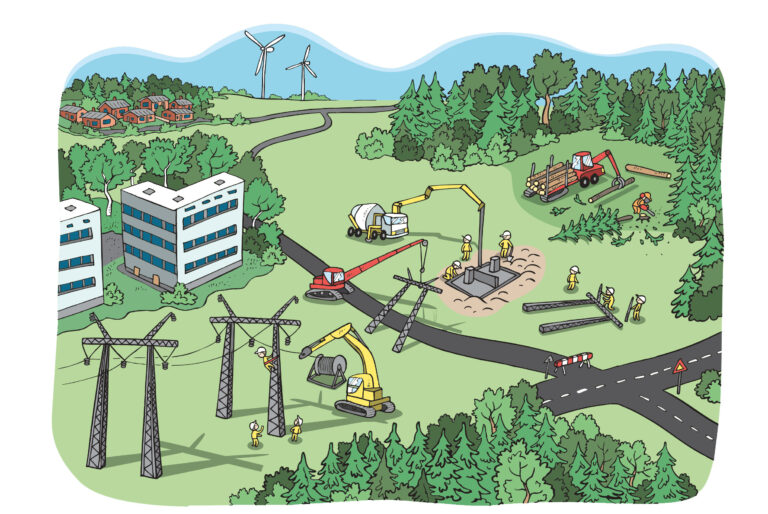

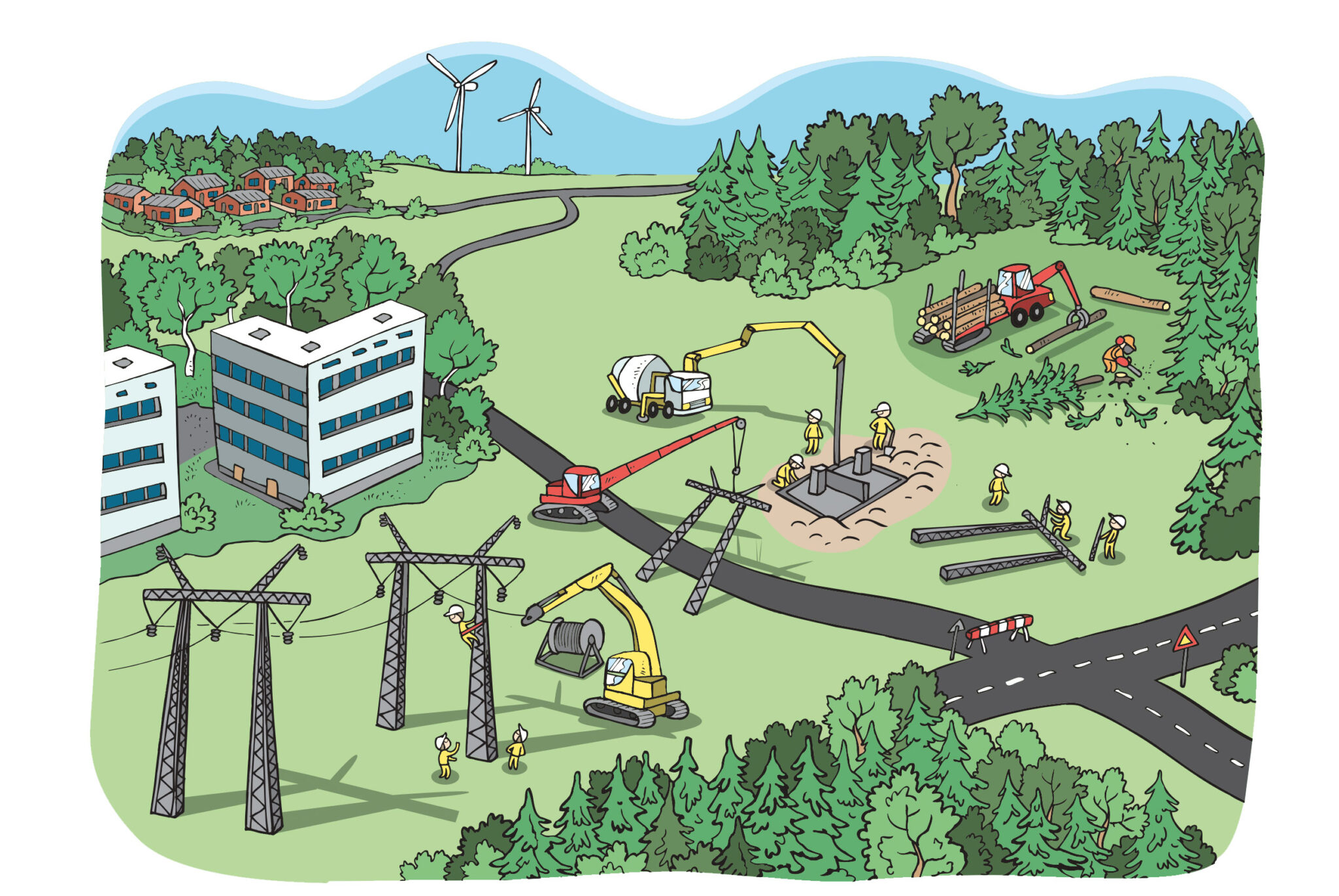

Solution based on Power to X technology

The production of synthetic methanol is based on Power to X technologies that make use of electricity generated from renewable sources when new products are developed. A project is underway to produce methanol using the hydrogen created as a by-product by the Kemira chemical plant in Joutseno and carbon dioxide, which is obtained from the chimneys of Finnsement Oy’s cement plant in Lappeenranta.

“Hydrogen has been produced by electrolysis for more than 100 years, but capturing carbon dioxide from the air is a new approach. From the perspective of a technically and financially feasible production plant, it is essential that the sources of methanol are located in areas where adequate renewable energy sources are available,” says Partanen.

Investment decisions expected in the autumn

According to Partanen, Finland has a head-start in the production of synthetic fuels compared with many other countries.

“We have a lot of cement factories and pulp mills whose processes give rise to sufficient quantities of carbon dioxide as a by-product. Cost-effective renewable energy is also required, and the excellent wind conditions in Finland are conducive to this,” says Partanen.

The project for a synthetic methanol plant has attracted a great deal of interest. In addition to Finnsement and Kemira, Neste, St1, Wärtsilä, Finnair and the Shell Research Centre Amsterdam (STCA), are also involved.

Premekon, Terästorni, Jotex Works and Redinec, local enterprises in the manufacturing industry, have been involved in financing the exploratory work for the project, as has the City of Lappeenranta.

“The aim for this autumn is to obtain enough research data for analysis to enable industrial enterprises to make their own investment decisions. Everything is going as planned, but we have not yet reached the final phase. So far, the calculations indicate that the project is worth driving forward,” says Partanen.